Lathe machines are generally used

for machining cylindrical nature of general work. In addition, it is possible

to provide special enhancement to the capability of the machine. Attachments

are used on centre lathe to increase production and efficiency and widen its

scope of use for such works which are normally not carried out on this machine.

Types of attachments

The commonly used attachments

are:

(a) Taper turning attachment

(b) Ball turning attachment

(c) Thread Chasing Dial

(d) Eccentric turning attachment

(e) Grinding attachment

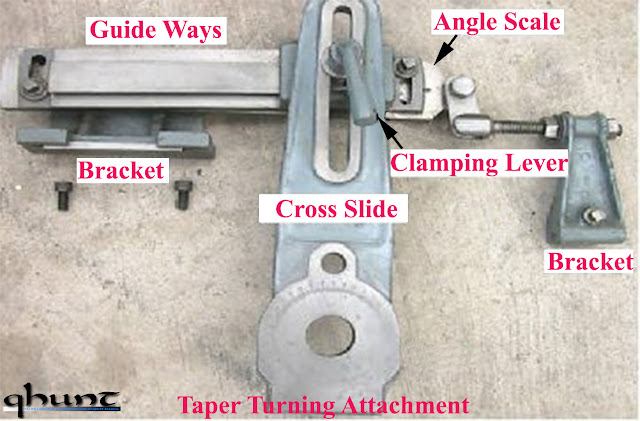

Taper Turning Attachment

The principle of turning taper by

a taper attachment is to guide the tool in a straight path set at an angle to

the axis of rotation of the workpiece. The

work is being revolved between centres or by a chuck aligned to the lathe axis.

A taper turning attachment consists essentially of a

bracket or frame which is attached to the rear end of the lathe bed and

supports a guide bar pivoted at the centre. The bar having graduations in

degrees may be swiveled on either side of the zero graduation and is set at the

desired angle, with the lathe axis.

When the taper turning attachment

is used, the cross slide is first made free from the lead screw by removing the

binder screw. The rear end of the cross slide is then tightened with the guide

block by means of a bolt. When the longitudinal feed is engaged, the tool

mounted on the cross slide will follow the angular path, as the guide block

will slide on the guide bar set at an angle to the lathe axis. The required

depth of cut is given by the compound slide which is placed at right angles to

the lathe axis. The guide bar must be set at half angle and the taper on the

work must be converted in degrees. The maximum angle angle through which the

guide bar may be swiveled is 100 to 120 on either side of the centre line.

If the large diameters (D), small

diameter (d) and the length of the taper (L) are given, the angle of swiveling

the guide bar can be determined from equation:

Advantages - The following are the advantages of the taper turning

attachment:

(a) The alignment of live and

dead centres being not disturbed, both straight and taper turning may be

performed on the work-piece in one setting without much loss of time.

(b) Once the taper is set, any

length of a piece of work may be turned taper within its limits.

(c) Accurate taper on a large

number of work pieces may be turned.

(d) Internal tapers can be turned

with ease.

Ball Turning Attachment

It is an attachment mounted on

the cross slide after removing the compound rest. It is used for turning

segment and sphere. It is in two halves, lower half and upper half. Lower half

is fixed with the cross slide and upper half can be rotated with the help of a

lever. There is a tool block on the top of the upper half in which provision is

made to hold the tool firmly. Tool block can be moved towards the centre or

away from the centre to facilitate the turning of different diameter

balls.

Thread Chasing Dial

When cutting threads one has to

take several cuts and for this the tool has to be withdrawn from the thread on

completion of each cut and again brought to starting position. If the tool does

not follow the path, the threads will be spoiled. So to achieve this, thread

chasing dial is fitted on the lathe. The chasing dial overcomes the difficulty

of catching the threads at correct start. It consists of graduated dial that is

connected to a

Worm wheel - The worm is in mesh with the lead screw, so that if

the saddle is stationary, the lead screw acts as a worm and rotates the chasing

dial. When the half nut is engaged, the tool starts travelling but the dial

remains stationary with one of the graduations opposite to the arrow. When the

cut is completed the saddle is returned to the starting point. When the nut is

disengaged and the dial remains rotating as soon as the graduated line comes

opposite to the arrow, the half nut can be engaged and the tool will follow its

original cut.

Eccentric Turning Attachment

It refers to the turning of

certain diameters at different lengths on the same shaft or jobs whose axis is

not falling in line with the main axis. A crank shaft of an engine is the

example of such job. This type of attachment is equipped with the provision of

shifting the centres of the work away from the lathe spindle axis. An accurate

marking and truing is of prime important in the sequence of operation of jobs

of this nature.

Grinding Attachment

It is also called tool post grinder. It is

mounted on the compound rest in place of tool post. This attachment consists of

a base plate, grinding wheel and a motor. The job is held in a chuck or between

centres. It is extensively used for grinding lathe centres in position. With

this attachment many other grinding operations can be performed on the lathe.

It is a useful attachment, which can be mounted on any lathe. It can grind

hardened work and ensures a fine finish. Internal grinding can also be done

with this grinder.

No comments