There are 12 types of operations which can be performed on a Milling Machine. Large varieties of components are manufactured on a milling machine involving the below mentioned various types of operations. These different types of milling operations performed on a milling machine are mentioned below.

- Plain milling

- Face milling

- Side milling

- Straddle milling

- Angular milling

- Gang milling

- Form milling

- Profile milling

- Helical milling

- Cam milling

- Thread milling

- End milling

- Die Sinking

Plain Milling Operation

The

plain milling is the operation of producing of a plain, flat surface parallel

to axis of the milling cutter. The operation is also called slab milling. This

operation is carried out with the help of plain or slab milling cutter.

|

| Plain Milling Operation |

Face Milling Operation

This

operation is performed by a face-milling cutter rotated about an axis

perpendicular to the work surface. The operation is carried in a plain milling

machine and the cutter is mounted on a stub arbor to produce a flat surface.

Side Milling Operation

The

side milling is the operation of production of a flat vertical surface on the

side of a work piece by using a side-milling cutter. The depth of cut is

adjusted by rotating vertical feed screw of table.

Straddle Milling Operation

The

straddle milling is the operation of production of flat vertical surfaces on

the both sides of a work piece by using two side milling cutters mounted on the

same arbor. The distance between the two cutters is correctly adjusted by using

suitable spacing collars.

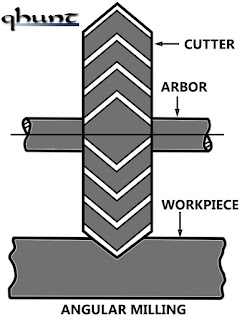

Angular Milling Operation

Is

the operation of production of an angular surface on a work piece other than

right angles to the axis of milling machine spindle? The angular groove may be

single or double angle and may be of varying included angle according to the

type and shape of the angular cutter used.

Gang Milling Operation

This

is the operation of machining several surfaces of a work piece simultaneously

by feeding the table against a number of cutters having same or different

diameters mounted on the arbor of the machine.

Form Milling Operation

The

form milling is the operation of production of irregular contours by using form

cutters. The irregular contour may be convex, concave or of any other shape.

Profile Milling Operation

It

is a reproduction of an outline of a template or complex shape of a master die

on work surface.

Helical Milling Operation

It

is the operation of production of helical flutes or grooves around the

periphery of a cylindrical or conical work piece. Swivelling the table to the

required helix angle to performs the operation. Then by rotating and feeding

the work against rotary cutting edges of a milling cutter.

Cam Milling Operation

Cam-milling

is the operation of production of cams in a milling machine by the use of a

universal dividing head and a vertical milling attachment. The axis of the cam

blank and the end mill spindle should always remain parallel to each other when

set for cam milling.

Thread Milling Operation

The

thread milling is the operation of production of threads by using a single or

multiple thread-milling cutters. The operation is performed in a special thread

milling machines.

End Milling Operation

The

end milling is the operation of production of flat surface which may be

vertical, horizontal or at an angle in reference to the table surface. The

cutter used is an end mill.

Die Sinking Operation

Dies

for drop forging, die-casting and sheet metal forming have impression or

cavity. The operation of cutting this impression or cavity in the die is called

die sinking. A simple or plain type diesinker is similar in its general

arrangement to a vertical-milling machine. The cutters used are such which will

assist as far as possible obtaining whatever shape required for die cavity.

Many devices and attachments for die sinking machine have been designed to

eliminate chipping and other different hand operations. For example die-sinking

machine have been equipped with a ‘cherrying head’ for milling circular

impression in the dies. A die-sinking machine is known as universal type, is so

designed that both cherrying and straight die sinking operations can easily be

performed without special attachments or cutters.

Note - Cherrying relates to the operation

of milling circular or special impression in the dies. Routing is milling a

more or less irregular outline while guiding by hand.

No comments